This time, in our ‘Brief History of…’ series, we look at Road Compactors. From horse drawn to autonomous, and how they’ve literally shaped our roads.

Since the first Roman Roads were built somewhere around 4000 BC, road construction has been developing and evolving. The first Roman roads were stone paved, however as roads started to be laid with alternate materials such as soil, gravel, concrete and asphalt, a new invention was required to flatten the material after it had been laid. The basic design of this invention, the Road Compactor, is similar today as it was in its first generation.

Image Courtesy of

Gun Powder Ma / CC BY-SA

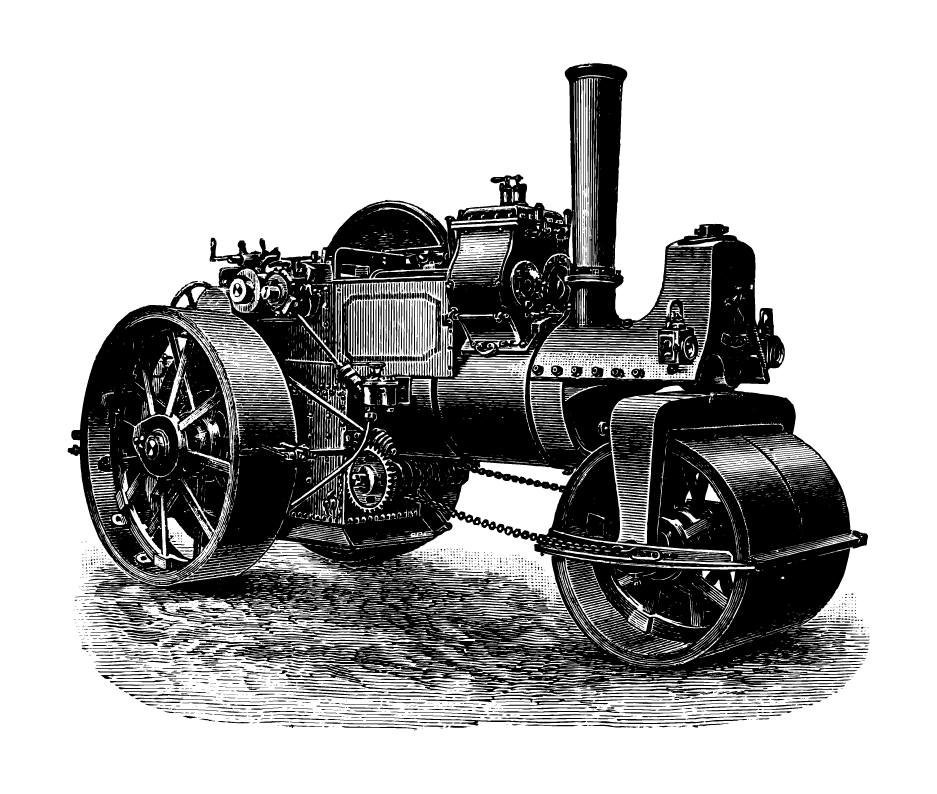

The first road rollers, such as the one pictured above, were likely horse drawn. These rollers were probably borrowed from agricultural uses and are similar to those still pulled by tractors to flatten farmland today. However, these contraptions were not ideal. The efficiency of a roller is, to an extent, dependent on the weight of the barrel. A horse drawn roller is less efficient than a self propelled roller for two main reasons: firstly, the fact that a horse can only pull a roller of a certain weight, secondly, he force of the roller pushing down on the road is diminished by the force of the horse pulling the roller forwards. Therefore, a horse-drawn roller is less successful than a self propelled vehicle.

Roller Compactors: The Steam Engine

In the late 1800s, the steam roller was invented. These machines usually comprised a 3-roll configuration, with two large wheels – known as rolls – to the back of the vehicle and one wide roll to the front. The design for original steam rollers was based on traction engines, which were self propelled steam engines used to transport heavy loads. However, there are key design features that set the steam roller and traction engine apart. These include the wheels, the placement of the machine’s smoke box, and special equipment such as scraper bars.

advert:

The steam roller worked in a similar way to modern road compactors. The levelling action being achieved through a combination of the weight of the machine, the rollers and, to an extent, the vibration of the engine.

The most famous exporter of Steam rollers in the UK was Strood based Aveling and Porter. The company built more steam rollers than any other British manufacturer combined.

SG2012 / CC BY

The machines were still widely in use into the 20th Century. In fact, part of the M1 motorway was made with the help of Steam rollers. This may go some way to explain why modern road compactors are still sometimes referred to as steam engines.

Road Compactors in the Modern World

Today, road compactors are usually powered by diesel engines. The machines come in a host of configurations from pedestrian operated to ride on machines. Over recent years, modern technology has played an important role in the development of road compactors.

In 2019, leading manufacturer of Road Rollers, Bomag announced the introduction of the ROBOMAG. This tandem roller is a fully autonomous machine with the capability to work independently within a predefined work area. he system obtains information on position, situation and movement using a combination of different technologies for spatial orientation, environmental perception and environmental safety. A comprehensive safety concept with sensory environment recognition is used to prevent collisions. This machine proved a popular attraction for attendees at Bauma and Plantworx in 2019.

In March 2020, Volvo CE introduced the DD128C compactor. The company claims that the compactor delivers the fastest rolling speeds whilst maintaining proper impact spacing. Further, modern technology has allowed for more advancements in the engine of the machine. The DD128C is powered by an advanced 110 kW(148 hp) Volvo D4 Tier 4 Final engine, which delivers high torque at low rpm, ensuring high-quality performance with minimal noise and fuel consumption. Engine operating speed during work mode is 1,850 rpm, providing the torque and power needed without the noise and fuel draw. Efficiency is further enhanced with optional auto-idling and auto-engine shutdown features. The engine and hydraulics are designed to work together to provide quick eccentric start times and exceptional drum performance in the most demanding conditions.

Road construction has come a long way since the use of the horse-drawn rollers of the 1800s. Improvements in engine technology, especially over the last 50 years, have ensured the machines used to build our roads are as efficient as possible.

The latest issue of Plant Planet is available online now.

Read the latest construction machinery news here.

Get updates on the go, follow us on Twitter.